The Williams Company, Inc.

Producing quality machined parts since 1937

Capabilities

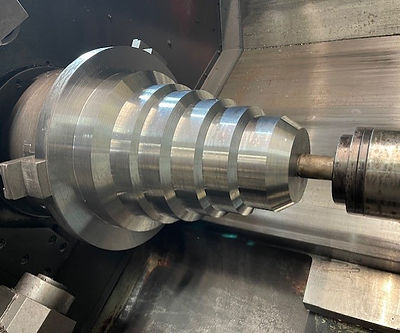

Advanced CNC machining with 17 machining centers including horizontal and vertical mills, turning centers, and comprehensive inspection capabilities.

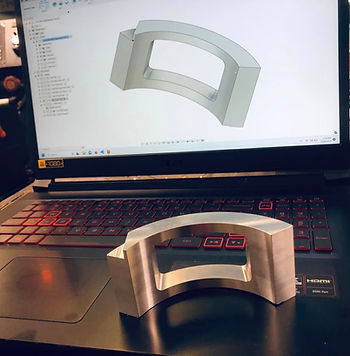

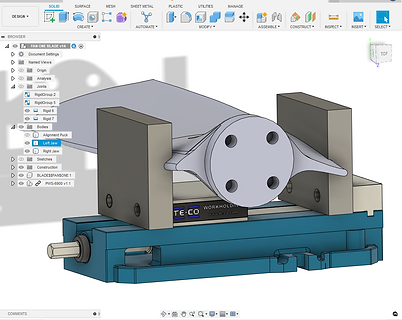

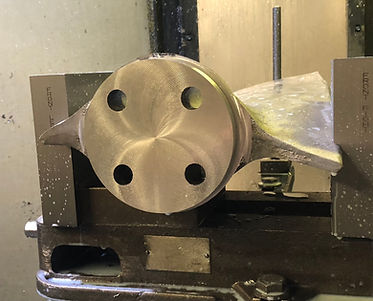

Our experienced machinists and operators utilize advanced CNC machining capabilities with 17 machining centers, including horizontal and vertical mills, as well as turning centers, to produce quality parts. We utilize the latest in CAD/CAM software for developing machine programming.

CNC Machining

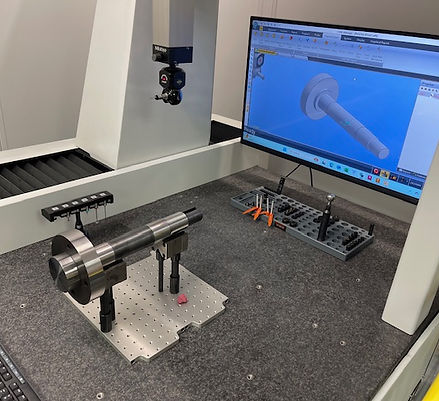

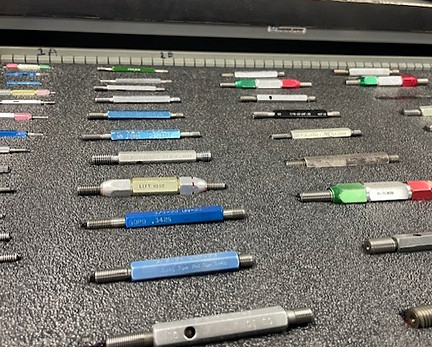

Quality Inspection

We ensure the quality of your products with our comprehensive inspection capabilities and processes (pre, mid, and final part run inspections). We strive for precision and accuracy in every part we produce.

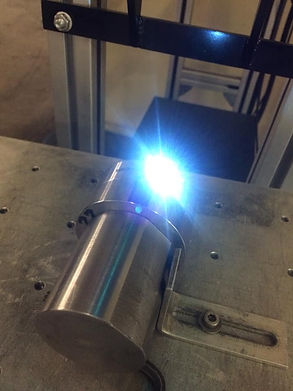

Laser Marking

The Williams Company utilizes a Keyence Laser for any in-house marking of machined parts requiring this identification process. We also offer this as a separate service for any part marking/identification needs.

TENSOMETER

The Williams Company, Inc. also provides manufacturing and repair services for Andritz Fabrics and Rolls, fabric tensometers (1200 series only). These tension measuring devices are essential to the paper and fibers industries. Our company has been manufacturing these tensometers for more than 55 years.

History: From 1937 to Present

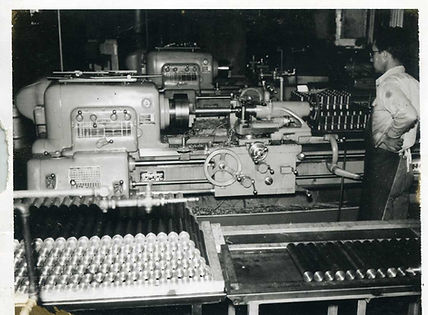

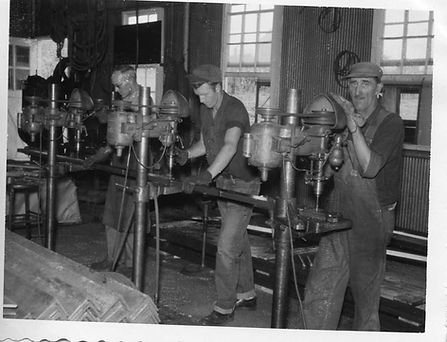

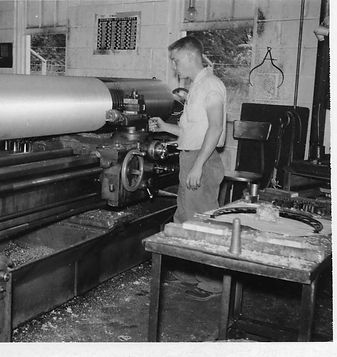

Father and son, Joseph Cicero and J.C. Williams, Jr organized the Williams Company in 1937. Founder Joseph Cicero Williams moved to Bristol, Tennessee around 1910 to work for Enterprise-Black Diamond Company, a large Bristol, Virginia machine shop specializing in mining cars and tractor-trailer bodies. In 1937, Joseph Cicero and his son J.C. Williams, Jr., started The Williams Company, Inc. in Bristol, Virginia. The original shop buildings were designed by Joseph Cicero and built by company employees.

The Williams Company, Inc. specialized in parts for the textile and fibers industries. North American Rayon, American Bemberg, and Tennessee Eastman were major customers until World War II. During the war, The Williams Company did work for Curtis Wright Aircraft, The Manhattan Project in Oak Ridge, Tennessee, and continued work for the essential rayon tire and fiber industry. This work continued until the end of the Korean War.

In the early 1950s, The Williams Company started to manufacture trailer bodies, designed by Joseph Cicero, for the trucking industry, which provided lightweight, but strong bodies. They were sold primarily to local moving and trucking companies. A uniquely designed insulated milk truck was also designed by Joseph Cicero and built by The Williams Company for the Pet Milk Company. These products were discontinued in the late 1950s. Joseph Cicero remained President and Manager until the late 1950s. J.C. became President and was instrumental in bringing Numerical Controlling Machining to The Williams Company around 1973. In 1971, Harry J. Williams followed his grandfather and father into the family business. Harry, a mechanical engineer, led the company as it transitioned to predominately CNC machining for the decades to come.

In 2020, Greg Hill, a former employee who had worked closely with previous owner Harry Williams, purchased the company. Under Greg’s leadership, The Williams Company continues to uphold its tradition of quality while embracing modern advancements in manufacturing.

The facility spans 20,000 square feet and houses 17 advanced CNC machining centers, including turning, vertical, and horizontal milling capabilities. Additionally, the shop is fully equipped with a comprehensive inspection department to ensure consistent accuracy and quality across all projects.

With a long-standing reputation and a commitment to excellence, The Williams Company serves a diverse range of industries supplying quality machined parts.